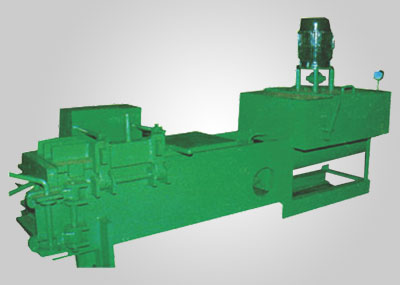

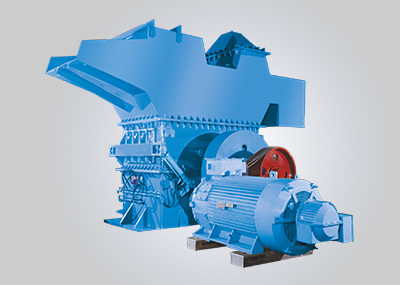

Briquetting Machines

Call : +91 9871296620

Today, nobody should produce waste for the simple ecological, economic and moral factors. The Foundries, Metallurgical & industrial enterprises and craftsman’s establishments are asked to take the waste back into the energy circuit as often as possible. Waste materials can become valuable secondary raw materials once they are briquetted & can be re-used by smelting. The cast iron dust is transformed back to cast iron; Metal chips / Turnings are reduced and converted to metal again with high recovery; Toxic materials can be reduced in volume and converted to vitrified slag which can be dumped or for reuse in road construction etc.

Our briquetting machines can produce briquettes which have been compressed at a ratio of up to 1:25. These briquettes can be smelted with almost no losses. The machines can also press out any oils or emulsions which may be adhering to machining chips. The compression of scrap to the extent of 5000 kg/sq cm ensures that almost every possible metal & waste gets briquetted without molasses or any other adhesive. Such considerable reductions in the volume of wastes lead to significant savings in the haulage and storage costs and minimise the losses incurred during smelting. Due to the great value of the reclaimed material, many companies see a pay back on their capital investment in 3 to 12 months.

Technicals

| Briquette Diameter | Electric Motor | Ferrous | Aluminium | Copper | Lead | Zinc | Tin | ||||||

| Bale Weight | Production / Hr | Bale Weight | Production / Hr | Bale Weight | Production / Hr | Bale Weight | Production / Hr | Bale Weight | Production / Hr | Bale Weight | Production / Hr | ||

| Inch | hp | Kg. | Tons / hr |

Kg | Tons / hr |

Kg | Tons / hr |

Kg | Tons / hr |

Kg | Tons / hr |

Kg | Tons / hr |

| 3 | 80 | 3-5 | 0.54 – 1.2 | 1 – 2 | 0.18 – 0.48 | 3 – 6 | 0.54 – 1.44 | 4 -7 | 0.72 – 1.68 | 3 – 5 | 0.54 – 1.2 | 3 – 5 | 0.54 – 1.2 |

| 4 | 80 | 5-7 | 0.9 – 1.68 | 2-2 | 0.36 – 0.48 | 6 – 8 | 1.08 – 1.92 | 7 – 10 | 1.26 – 2.4 | 5 – 6 | 0.9 – 1.44 | 5 – 7 | 0.9 – 1.68 |

| 6 | 80 | 7-10 | 1.26 – 2.4 | 2-3 | 0.36 – 0.72 | 8 – 11 | 1.44 – 2.64 | 10 – 14 | 1.8 – 3.36 | 6 – 9 | 1.08 – 2.16 | 7 – 9 | 1.26 – 2.16 |

* The above data is indicative & not binding. This does not guarantee or contains assurances of any kind

* The performance data are strongly dependent on the type and composition of the input material, the feeding density as well as the qualification of the operator

* The company reserves all rights to introduce any modifications

* The equipment shall be under warranty for one year against any manufacturing defect from the date of supply

Benefits

The Nut Cracker “Briquetting Machines” are easy and economical in operation. The chips are fed inside the machine via hopper with adjustable screw conveyor. The automatic control system provided in the machine ensures uniform briquette length. Our Briquetting machines have relatively higher service life and ensure safety and trouble-free performance. They produce briquettes of higher densities with compaction to the ratios of 1:25 achievable.

The graphic display of the PLC not only shows all the operating and processing data but also assists with the troubleshooting, thereby reducing the machine operation downtime to the minimum.