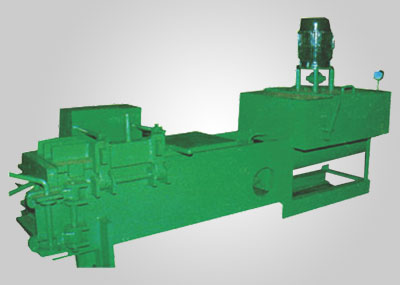

Casting Crackers

Call : +91 9871296620

Hydraulically operated Nut Cracker’ Casting Crackers are designed for the effective crushing of overflows from the aluminium die-casting, Engine Blocks, Aluminium heads etc. The casting cracker wear and tear of the crushing area lining is cut down to the barest minimum as the cracking of the runners / risers is done without the grinding effect. The scrap is broken down into small non-uniform portions, which enables the increased recovery of the primary metals while remelting. Thus, the Nut Cracker casting crackers have proven to be a verdana for the aluminium die-casting divisions.

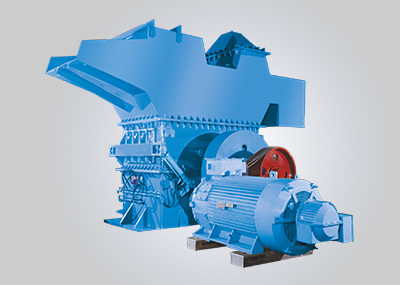

Benefits

- Automatic sequence of cracking operations

- Little dust formation

- Number of strokes for crushing procedure can be adjusted according to requirements for the material to be processed

- Finer or coarser final granulation can be achieved by stated pressure variations.