Bio-Medical Waste Sterilizer

Call : +91 9871592211

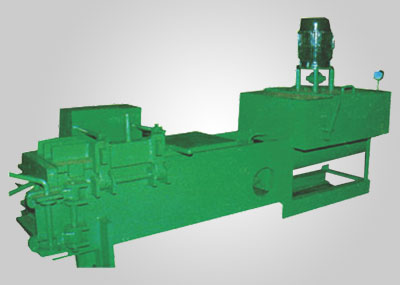

Bio-Clave –Bio-Medical waste sterilizer

Steam sterilization equipment for Bio-Medical waste treatment

It is an advanced form of autoclave as mentiond in C.P.C.B. Manual, March 2000. The waste is heated indirectly by providing steam in the jacked instead of main chamber. The moisture in the waste is used to generate the necessary steam pressure for most optimum sterilization at minimum (Least) cost. Uses Principle of Hydrolysis to treat the waste.

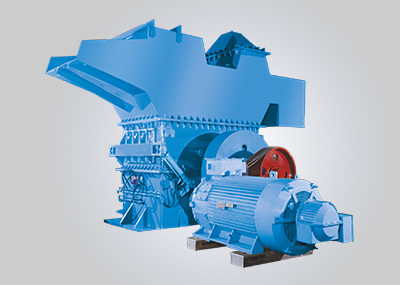

The system is totally Micro-processor controlled and highly automated. No Human effort is required except putting waste bags inside the vessel. The waste loading door closes automatically, preshredding is done inside vessel resulting in Homogeneous nature of the waste inside the equipment thus allowing for maximum penetration of steam to each and every part of the waste. The unloading of the waste is by the tumbler arm and tumbler tilt, both operate fully synchronized and automated without any human effort, Final discharge on to the shredder and then to the storage bins (optional).

Preshredding inside the Indirect Steam Heating System Technology results in total fragmentation of waste. The rotating arm makes the waste to continuously move around. This mechanism ensures total sterilization and avoid any cold spots which are there in autoclaves.

The very important feature is that it treats the wateto the level of 6-LOG, which is equivalent to 99.999, almost 100%.

One man even with a little technical skill can operate the total machine. He is to only monitor the display and follow the manual just siting over the control panel. The final process chart comes out explaining the total processs prameters graphically.

The steam in the main chamber is sucked and drained to the sewer at very high temperature and pressure and is totailly sterile.

There is no water effluents of the equipment or if are, very small which is totally sterile and can be disposed off through the sanitary sewer.

In this system the volume of waste reduces upto 85% and weight reduces upto 70%.

From the main chamber moisture is totally converted into steam making the waste totally dry.

An innovative type of steam Sterilization equipment and eco-friendly technology most suitable to the moisturised waste, which is generated in Asian Countries.

It is a trippled walled chamber Waste Sterilizer.

It is a most advanced Indirect Steam Heating System Technology.

Bio-Medical waste Sterilization through Indirect Steam heating.

A fully automatic equipment with PLC (Micro- Processor) control.

A machine with high level of safety features and programmed to handle automatically with continous feed back available to operator.

No operation starts until feeding platfrom gate is closed.

Human resource required only for feeding. Emergency Stop, Hooter and Light.

Bio-medical waste sterilization though indirect steam heating.

EQUIPMENT CAN ALSO BE SUPPLIED WITH AUTO FEEDING DIRECTLY FROM BINS INTO THE BIO-CLAVE CHAMBER. UNLOADING OF BINS WILL BE FULLY AUTOMATIC AND LOADING OF BINS TO THE CHAMBER WILL ALSO BE AUTOMATIC.

NO HUMAN INVOLVEMENT.

Available in different sizes & capacity. Fully automatic, Semi-automatic & Manually operated.

Fully Indigenous Automatic Steam Sterilization technology

The equipment is PLC(Micro-Processor) Controlled & highly automated