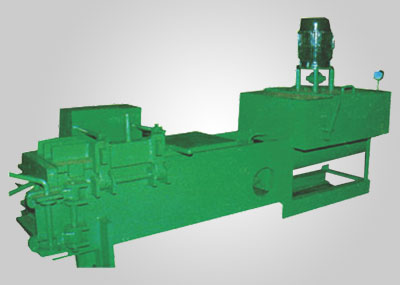

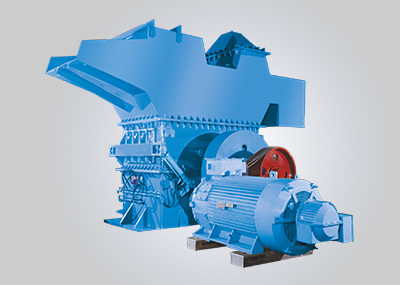

Pre-Sredders/Twin Shaft Shredders

Call : +91 9871592211

Nut Cracker pre-shredders are capable of processing 5-100 tons of ferrous scrap per hour including:

- Complete cars with or without engines or flattened condition

- White Goods such as household appliances, washing machines, refrigerators, etc

- Any Iron and steel scrap up to 8 mm thick

- Hard packed bales

These pre-shredders allow smaller shredders to process heavier materials in lesser time. This enables a stress free operation of the shredder machine due to reduction of explosions and lesser downtime. The throughput increases due to the homogenisation of the in-feed material. The hammers used in the Nut Cracker pre-shredder machines are manufactured out of costly, special alloy steel cold rolled castings containing 11-14% Mn, 1.0-1.3% C, Si, P & S in the required proportions. The wear parts used in the machine are manufactured from such work hardened steel alloys in the local foundries under strict quality control measures. All such parts are of highest quality of steel alloys in order to resist the wear & tear. These pre-shredders enable the best densification & liberation inside the main shredder plant thereby allowing a perfect separation downstream.

Salient Features

- Special grade steel is used for hammers and mesh for longer maintenance free life

- Specially designed heavy duty rotors with hammers pre-shreds the in feed scrap into smaller portions that are free from dust & rust

- Easy & continuous charging of scrap via input conveyer or a grabber

- Metal sorting equipments can be attached in line with the output mesh

- Rigid & Sturdy in construction with heavy ribs & stiffeners to bear the overall impact of pre-shredding

Benefits

The Nut Cracker “Pre Shredders” are simply sturdy & rugged and allows the smaller shredding plants to process heavier materials. These metal pre-shredders enable stress free operations due to the reduction of explosions thereby avoiding various environmental hazards. These helpers further result in lesser wear and tear of the main shredder unit and its parts which inturn lead to lesser downtime of the system.

The Nut Cracker pre-shredder units also increase the throughput of the system due to the homogenisation of in-feed material. This results in the best densification and liberation inside the main shredder unit and allows a perfect separation downstream. The reduction of peak loads in frequency and size result in lower electricity costs & lesser energy consumption. Thus, our pre-shredders lead to the wholesome increased life of wear parts as well as the whole aggregate.