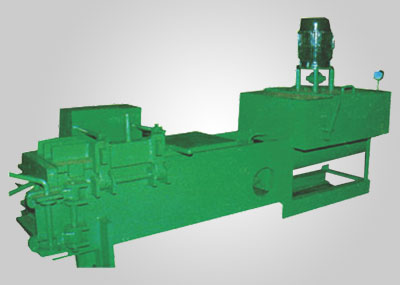

Double Action

Call : +91 9871592211

A Double Action baler presses the scrap from two sides i.e. from the Top & Length wise. Small & compact, such a baler is best suited for medium sized scrap traders. The baler is operated by two manually operated Direction Control Valves, one to operate the top lid cylinder& the other to operate the rear pressing cylinder. Basic in design, such balers call for minimal trouble shooting.

Alternatively, these baling machines can also be PLC controlled as per the requirement of the customer. The carefully planned construction of these waste balers is sturdy and durable due to extensive wear protection. The common wear parts of the compactors can be easily replaced, without having to remove the complete compactor units. An automatic lubrication system results in virtually trouble-free operation and minimum wear. The operation and troubleshooting can easily be performed on the multi-information PLC display of the waste baler. The terminal consists of a display that shows all process-relevant information and status reports.

Technicals

| Pressing Chamber Size | Bale Size | Electric Motor | Papper | Plastic (PET) | ||

| Bale Weight | Production / Shift | Bale Weight | Production / Shift | |||

| Inch | Inch | hp | Kg. | Tons / Shift | Kg | Tons / Shift |

| 52x 24 x 20 | 12 x 24 | 20/25 | 35 – 45 | 7 – 10.8 | 15 – 25 | 3 – 5 |

| 60 x 24 x 24 | 12 x 24 | 30 | 49 – 63 | 9.8 – 15.12 | 21 – 35 | 4.2 – 7 |

* The above data is indicative & not binding. This does not guarantee or contains assurances of any kind

* The performance data are strongly dependent on the type and composition of the input material, the feeding density as well as the qualification of the operator

* The company reserves all rights to introduce any modifications

* The equipment shall be under warranty for one year against any manufacturing defect from the date of supply

Benefits

The Nut Cracker “Double Action Balers” are easy & economical in operation by two manually operated direction control valves provided on the power pack of the machine. These balers are typically maintenance free and call for minimal power consumption. Such baling presses are best suited for small processing applications where cheap labour is easily available.