Triple Action

Call : +91 9871592211

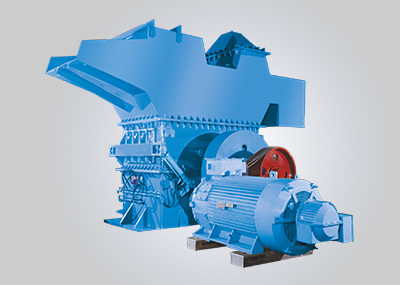

A Triple Action baler presses the scrap from three sides i.e. from the Top, Length wise & Side ways. Such balers are best suited to meet the high production requirements and produce significant cost savings during the scrap transportation. These also enable the maximum feeding of scrap in the EAF during the heat. These balers are available in various sizes and with various capacities.

The Nut Cracker make triple action scrap baling presses comprises a number of different, triple compressing scrap balers. For every application there is a suitable scrap baling press. Each scrap baler is equipped with three separately operating compactors that press the scrap material into compact bales. The drive and control concepts of the scrap baling presses allow an efficient operation with particularly low energy consumption and maximum throughput capacity.

The carefully planned construction of these waste balers is sturdy and durable due to extensive wear protection. The common wear parts of the compactors can be easily replaced, without having to remove the complete compactor units. An automatic lubrication system results in virtually trouble-free operation and minimum wear. The operation and troubleshooting can easily be performed on the multi-information PLC display of the waste baler. The terminal consists of a display that shows all process-relevant information and status reports.

Technicals

| Pressing Chamber Size | Bale Size | Electric Motor | Papper | Plastic (PET) | ||

| Bale Weight | Production / Shift | Bale Weight | Production / Shift | |||

| Inch | Inch | hp | Kg. | Tons / Shift | Kg | Tons / Shift |

| 55x 22 x 20 | 12 x 14 | 30 | 40 – 50 | 8 – 12 | 15 – 25 | 3 – 5 |

| 60 x 30 x 24 | 12 x 14 | 40 | 48 – 60 | 17.28 – 19.2 | 18 – 30 | 6.48 – 10.8 |

* The above data is indicative & not binding. This does not guarantee or contains assurances of any kind

* The performance data are strongly dependent on the type and composition of the input material, the feeding density as well as the qualification of the operator

* The company reserves all rights to introduce any modifications

* The equipment shall be under warranty for one year against any manufacturing defect from the date of supply

Benefits

The Nut Cracker “Triple Action” balers are easy & economical in operation by the push levers provided on the power pack of the machine. Such balers are best suited to meet higher production requirements and produce significant cost savings during the scrap transportation. These waste balers also enable the maximum feeding of scrap. The Triple Action baling presses are available in various sizes and with various capacities. These are capable of compacting virtually all waste scrap into dense square bales