In the global pursuit of sustainability, recycling stands as a beacon of hope, offering a tangible solution to mitigate environmental degradation and resource depletion. At the heart of the recycling industry lies a critical piece of equipment: the baling machine. These mighty machines play a pivotal role in transforming recyclable materials into compact, transportable bales, thereby revolutionizing the efficiency and effectiveness of recycling operations. Let’s delve into the world of baling machines and explore why they are indispensable for the recycling industry.

Unveiling the Role of Baling Machines

Baling machines, also known as balers, are specialized equipment designed to compress and bind various types of recyclable materials into dense, uniform bales. These materials may include cardboard, paper, plastics, textiles, aluminum cans, and more. By compacting loose recyclables into bales, balers facilitate easier handling, storage, transportation, and processing of materials, thereby streamlining recycling operations and maximizing resource recovery.

The Importance of Baling Machines in Recycling

1. Maximizing Space Efficiency:

Balers significantly reduce the volume of recyclable materials, allowing for efficient use of storage space in recycling facilities, warehouses, and transportation vehicles. By compressing materials into dense bales, balers minimize the footprint required for storage and transportation, optimizing space utilization and reducing logistical costs.

2. Enhancing Transportation Logistics:

Compact bales are easier to handle and transport compared to loose materials. Balers enable recyclers to load more materials onto trucks, containers, or railcars, thereby maximizing payload capacity and reducing the frequency of transportation trips. This results in lower fuel consumption, reduced emissions, and overall cost savings in the logistics chain.

3. Improving Material Quality:

Baling machines ensure the uniform compression and binding of recyclable materials, resulting in consistent bale dimensions and weight. This standardization enhances the quality of materials for downstream processing, sorting, and recycling, minimizing contamination and maximizing the value of recovered materials.

4. Facilitating Material Handling and Processing:

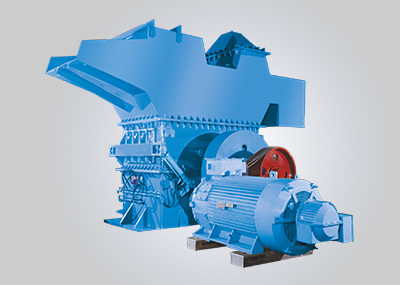

By converting loose materials into compact bales, balers simplify the handling and processing of recyclables for recycling facilities and end-users. Bales can be easily stacked, sorted, and fed into shredders, granulators, or other processing equipment, streamlining material recovery processes and improving operational efficiency.

Types of Baling Machines

There are several types of baling machines tailored to different recycling applications and material types:

- Vertical Balers: Ideal for small to medium-scale operations, vertical balers compact materials vertically and produce bales of varying sizes. They are commonly used for cardboard, paper, plastics, and textile recycling.

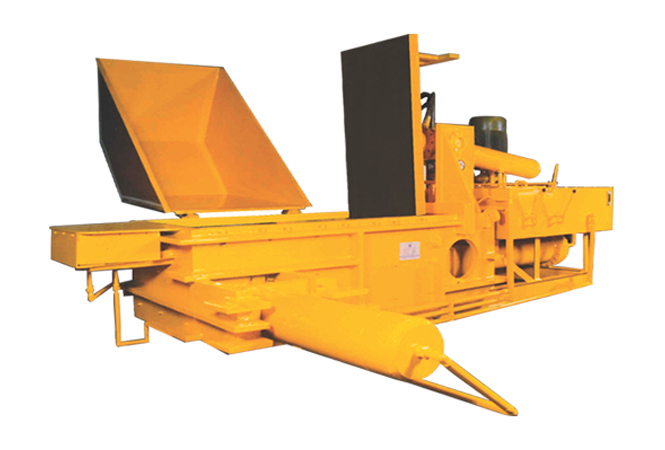

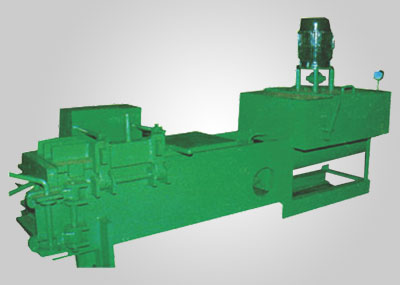

- Horizontal Balers: Horizontal balers are suitable for large-scale operations and high-volume recycling facilities. They compress materials horizontally and produce larger, heavier bales, making them well-suited for processing materials such as aluminum cans, PET bottles, and scrap metal.

- Two-Ram Balers: Two-ram balers feature two hydraulic rams for increased compaction force and versatility. They are capable of processing a wide range of materials, including mixed recyclables, plastics, and fibrous materials, while offering customizable bale sizes and densities.

Conclusion: Driving the Recycling Revolution

In conclusion, baling machines serve as the backbone of the recycling industry, facilitating the efficient processing and management of recyclable materials. With their ability to maximize space efficiency, enhance transportation logistics, improve material quality, and streamline processing operations, balers play a vital role in driving the recycling revolution forward. As the world embraces sustainability and circular economy principles, the importance of baling machines in recycling will only continue to grow, paving the way towards a greener, more sustainable future for generations to come.