In the dynamic world of metal recycling, the role of shredding machines cannot be overstated. These powerful tools are essential for breaking down bulky metal scrap into manageable pieces, paving the way for efficient processing and resource recovery. However, with a plethora of shredding machines available on the market, selecting the right one for your metal recycling operations can be a daunting task. Let’s embark on a journey to unravel the key factors to consider when choosing the best shredding machines for metal recycling.

Understanding Your Requirements

Before diving into the selection process, it’s crucial to assess your specific needs and requirements. Consider factors such as the type and volume of metal scrap you’ll be processing, the desired output size, throughput capacity, energy efficiency, and budget constraints. Understanding these parameters will guide you in narrowing down your options and identifying shredding machines that align with your operational goals.

Key Considerations When Choosing Shredding Machines

1. Type of Material:

Different shredding machines are designed to handle specific types of metal scrap, ranging from light gauge materials like aluminum and copper to heavy-duty steel and alloys. Ensure that the shredder you choose is capable of effectively processing the type of metal scrap you deal with regularly.

2. Shredding Capacity:

Assess the throughput capacity of the shredding machine, which refers to the volume of material it can process per unit of time. Choose a shredder with a capacity that meets or exceeds your production requirements to ensure smooth and uninterrupted operation.

3. Shredding Technology:

Consider the shredding technology employed by the machine, whether it’s a hammer mill, shear shredder, or granulator. Each technology offers unique advantages in terms of efficiency, versatility, and final particle size. Select the technology that best suits your processing needs and material characteristics.

4. Maintenance and Durability:

Opt for shredding machines that are built to withstand the rigors of heavy-duty metal recycling operations. Look for features such as robust construction, durable wear-resistant components, and easy access for maintenance and servicing. A reliable shredder will minimize downtime and maintenance costs, ensuring optimal performance over the long term.

5. Energy Efficiency:

Consider the energy consumption of the shredding machine, as well as any additional features or technologies that contribute to energy efficiency. Choosing an energy-efficient shredder can help reduce operating costs and minimize environmental impact, aligning with sustainability goals.

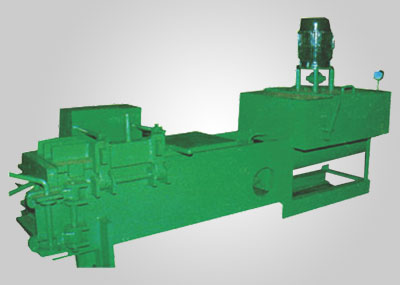

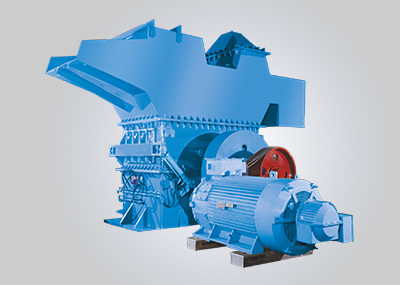

The Nut Cracker Advantage: The Ultimate Solution for Metal Recycling Shredders

After careful consideration of various shredding machine options, one name stands out as the epitome of excellence: Nut Cracker. Nut Cracker offers a comprehensive range of shredders specifically designed for metal recycling applications, combining cutting-edge technology, superior performance, and unmatched reliability.

Why Nut Cracker Stands Out:

- Advanced Shredding Technology: Nut Cracker shredders incorporate state-of-the-art shredding technology, including high-torque motors, precision-cutting blades, and intelligent control systems, ensuring efficient and consistent shredding performance.

- Customizable Solutions: Nut Cracker offers customizable shredding solutions tailored to meet the unique requirements of each customer. Whether you’re processing ferrous or non-ferrous metals, Nut Cracker has the expertise and capabilities to deliver shredders optimized for your specific application.

- Exceptional Durability: Built to last, Nut Cracker shredders are engineered with heavy-duty materials and components, ensuring durability and longevity even in the most demanding operating conditions. With minimal maintenance requirements, Nut Cracker shredders deliver reliable performance day in and day out.

- Energy Efficiency: Nut Cracker prioritizes energy efficiency in its shredding machines, incorporating innovative features and technologies to minimize energy consumption without compromising performance. This results in lower operating costs and reduced environmental impact, making Nut Cracker shredders a sustainable choice for metal recycling operations.

In conclusion, choosing the best shredding machines for metal recycling is a critical decision that requires careful consideration of various factors. With its unparalleled expertise, cutting-edge technology, and commitment to customer satisfaction, Nut Cracker emerges as the ultimate choice for metal recycling shredders. Invest in Nut Cracker shredders and experience the difference in performance, reliability, and efficiency for your metal recycling operations.